spark plug coil. If you notice any of these symptoms, it is important to have the spark plug coil inspected by a professional mechanic.

In conclusion, U-shaped silicone gaskets, white rubber gasket sheets, and waterproof rubber gaskets offer versatile and effective sealing solutions for a wide range of industrial and commercial applications. Understanding the advantages and applications of these gaskets is crucial for selecting the appropriate sealing components to ensure protection, reliability, and longevity in various systems and equipment.

How are they used?

There are a wide range of oil seals to select from for any number of uses, so this guide will break down the most common seals to help you choose the right one for whatever piece of machinery you are working on.

Replace the sump drain plug tightly and refill the engine with the right amount and grade of oil.

The rubber material used in the oil seal should be selected based on the operational temperature and substance to be sealed.

Table 5 lists the major rubber materials along with their operational temperature ranges.

Note that it is necessary to check the compatibility with fluids.

<N.B.>

Extreme pressure additives are compounds added to the lubricant. They are activated by heat and chemically react against rubber, which deteriorates rubber properties. For this reason, it is necessary to check for compatibility with rubber materials.

Obtaining adequate adhesion of fluoroelastomer compounds to metal inserts is a major consideration in fabrication of shaft seals. Adhesive systems worked out for bisphenol-cured VDF/HFP/TFE elastomers often do not perform adequately for peroxide-curable fluoroelastomers and more base-resistant polymers that contain little or no VDF. The trend toward use of more resistant fluoroelastomers in shaft seals has necessitated considerable effort on compounding and adhesive system development to get adequate bonding of the new materials. Silane-type primers are often used to coat metal inserts; these contain residual active groups such as amine functions that interact with the fluoroelastomer compound to attain good adhesion, especially for VDF/HFP/TFE elastomers. Other adhesive systems, using epoxy compounds or tie-coats, may be necessary for difficult bonding situations.3

Automotive Rubber Gaskets: Versatile Sealing Solutions

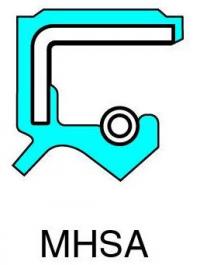

Spring Seals

A rubber or PTFE sealing lip

Carboxylate Nitrile

LED (Light Emitting Diode)

ERIKS type GV (type C according to DIN) is equivalent to type M, but is a heavy-duty version with a double metal casing. This can be a useful solution with larger diameters in more demanding applications. There is also a version of this type with a dust lip; the GVST (type CS according to DIN).